UNIT 175K

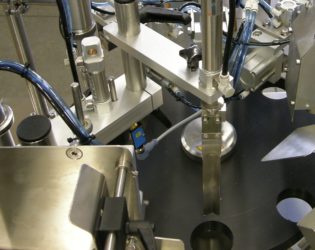

Advantage is the proven machine concept based on years of experience. The machine is based on the UNIT 125P type. The carousel type machine with an eight-position rotary table height-adjustable together with all adjustment elements of the bottom machine structure. The device is standardized with a tube orientation unit according to the printing label and tube inspection. Furthermore, it is a single-acting volumetric pump with a pneumatic drive and a cylindroconic funnel for the product. The funnel can be fitted with a cover lid with an ultrasonic level sensor. Other options include a product stirrer in the funnel or a two-way three-way slider designed to fill difficult products. Two pneumatically operated units with folding jaws are used to seal the tube.

| Production Output | 1 700 tubes / hour (depending on product type and tube) |

| Tube diameter range | 13-40 mm |

| Tube length range | 75-220 mm (without closure) |

| Filling volume | I. 5-40 ml continuously setting II. 20 - 240 ml continuously setting |

| Funnel volume | 32 l |

| Electrical system | 400/230 V, 50 Hz |

| Power consumption | 3 kW |

| Pneumatic components | SMC |

| Air pressure | 5-6 bar |

| Air consumption | up to 13.5 m3 / hour |

| Machine dimensions | length: 1 200 mm width: 950 mm height: 1 750 mm |

| Machine weight | 220 kg |

| Control system | Allen Bradley |