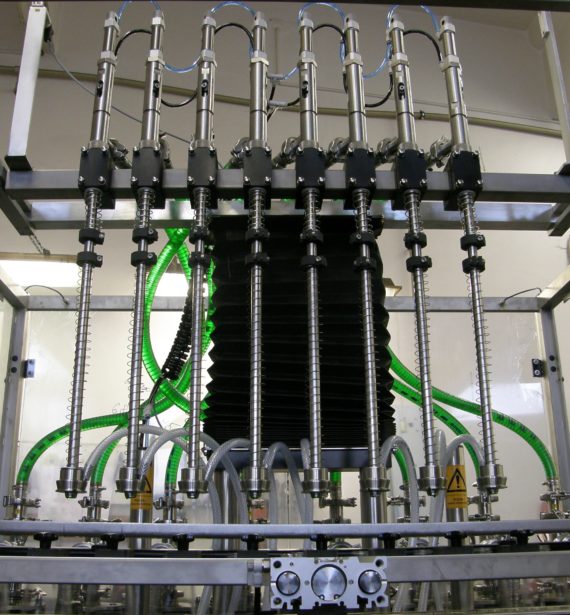

LP 8 (with filling cylinders)

The LP 8 linear filling device is designed to fill liquid, uncoated, low viscosity liquids into different types of packaging. The two-speed worm gear drives the horizontally mounted main shaft and the chain drive transmits the torque to the arms of the feed rollers. The size of the filled batch is adjusted mechanically by the adjusting screw – by changing the eccentricity of the crank pin. The LP 8 is equipped with a transverse link conveyor, which ensures the transport of empty containers under the filling needle and the displacement of filled containers for further operation. The number of filling points (needles) is modular (2x, 4x, 6x or 8x).

Are you interested or just want to ask something? Call us.

Loading packages into the machine:

- Fully automatic from a continuous conveyor

- conveyor length optional

Filler needle variants:

a) pneumatically closed plug

b) with blow of "hair"

c) with suction drops

Number of needle fillers:

- according to required parameters 2-8

- depending on the filled volume and diameter of the neck of the package

Filling principle:

- using piston filling cylinders

Moving finished products:

- Fully automatic on continuous conveyor

Used Materials:

- stainless steel AISI 304 (316L), PTFE (FPM, EPDM)

- SMC pneumatic elements

Control system and diagnostics

- Allen Bradley with own diagnosis

- tracking production history and error messages

- color touch touch control

| Production Output | Max. 2 800 pcs / hr. (depending on filled volume and neck diameter) |

| Filled volume | variable as required |

| Air pressure | 5-6 bar |

| Power consumption | 1,2 kW |

| Electrical system | 400/230 V, 50 Hz |

| Machine weight | 380 kg |

| Machine dimensions (without conveyor) | length 1 860 mm width 650 mm height 1 800 mm |

| Pneumatic components | SMC |

| Control system | Allen Bradley |